Download Center

Your one-stop destination for fast and secure access to all essential technical datasheets, product catalogs of the High voltage distribution box. Please feel free to download the attachment.

KRX18-500 Straight Plug_2D drawing

KRX18-500 Straight Plug_2D drawing

Gerneral Information

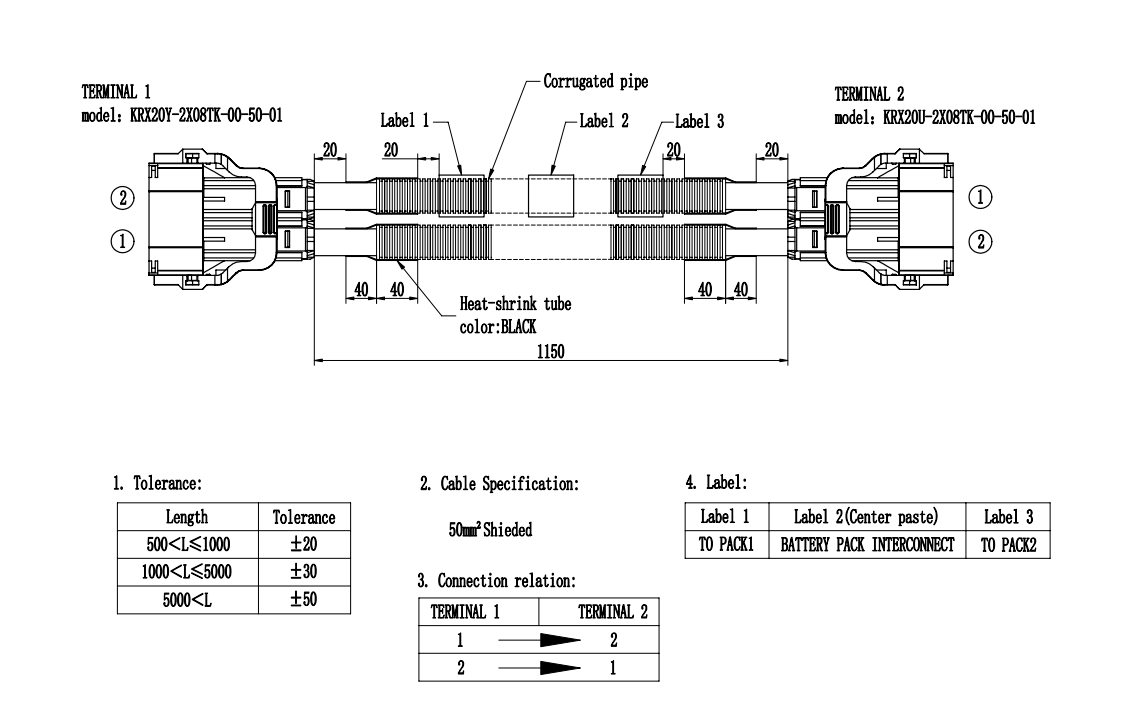

| Product Type | HV Wire Harness | Connector Options | KRX/TE/Amphenol/Jonhon, etc. |

Color | Orange | Crimping Range | 2.5 mm²-300 mm² |

Rate Current | 20A-800A | Withstand Voltage | 2300V |

Mounting Type | Terminal Crimp | Ingress Protection | IP67 |

Shield | Support | HVIL | Support |

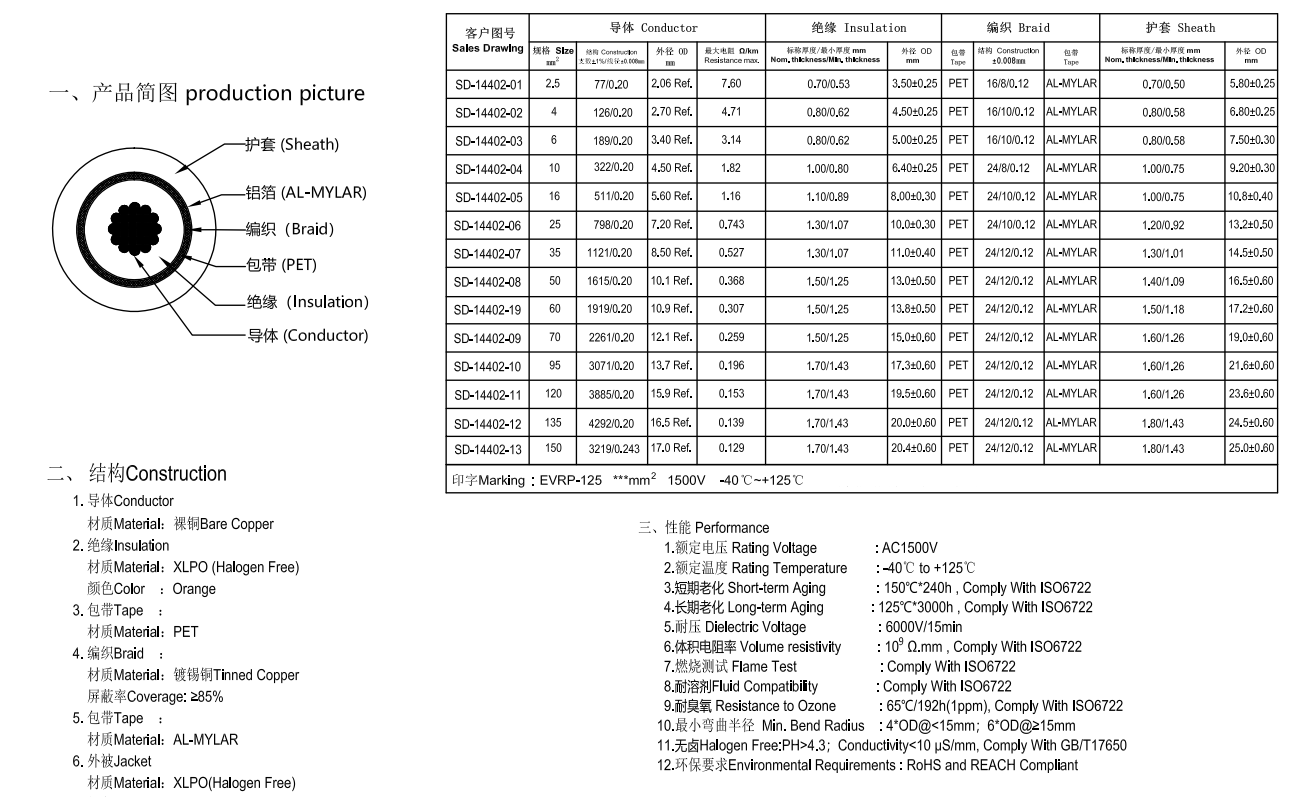

Material | XLPO (Halogen Free) | Temperature Range | -40°C ~ 125°C |

MOQ | No MOQ Limited | Custom Design | Support |

Production Timeline | 10-15 days | Packing Details | Carton or Wooden Case |

Features & Benefits

Provide wire harness processing services.

Standard connectors for quick and easy installation.

Crimping range: 2.5-300mm², the voltage upto 2300V.

100% breakover and high voltage test and air tight test.

Compliant with UL , REACH and RoHS specifications and certificate.

Full range of HV connectors for safe, reliable and efficient interconnection.

Full customized supports on all your high voltage interconnection requirements.

The shielded cable design shields up to 95% EMI coverage and complies with EMC requirements.

The cables are available in different sizes, lengths and configurations to meet the needs of your application.

The high voltage cable assemblies include unshielded cables , shielded cables, single and multi-core cables options.

The safe and reliable high voltage harness assemblies are combined with the most advanced technologies such as high voltage interlock loop (ensures safe interconnection between EV batteries and charge controllers), electromagnetic shielding (provides protection against electromagnetic interference) and mechanical shock response (protects against sudden impacts during road collisions or off-road driving conditions), to ensure safe interconnection of EVs.

Excellent Key Technologies

Our advantage

Safety Consideration

KRX's high-voltage wire harnesses are engineered for precision crimping and flame-retardant materials to prevent arcing or overheating. Every unit undergoes hi-pot testing (2500V+) and 100% continuity checks to ensure reliability.

Compliance & Certifications

KRX selects and uses high-voltage cables that have passed the UL, TUV, and REACH certificates, ensuring compliance with international safety and performance standards.

Precision Crimping Technology

Automated crimping processes with <2% tolerance for consistent contact resistance. 100% pull-test verification on all terminations. Silver-plated connectors to reduce oxidation

Quality Control & Testing

Our quality control system ensures every high-voltage wire harness meets the highest reliability standards through. In-line testing, 100% continuity checks, and environmental stress tests.

Customization & Compatibility

We specialize in collaborative wire harness development with OEM collaboration, modular designs, and rapid prototyping.

HV Cable Specification

Customer Cases Of Wire Harness Drawing

Product Applications

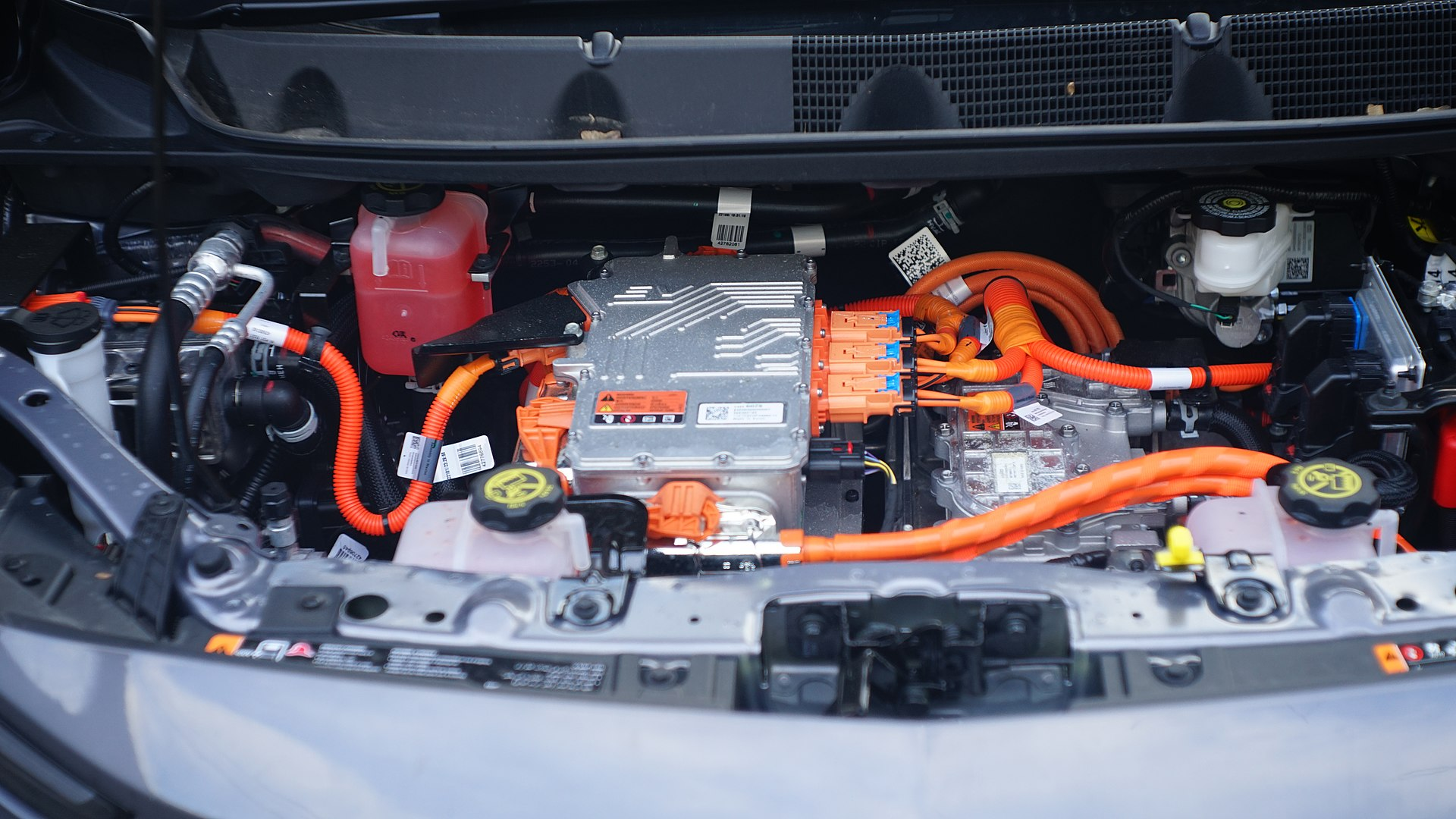

Our High-voltage connectors are used in a wide range of industries, including electric vehicles, electric boats, energy storage system, Evtol, railway transportation, etc.

DC-to-DC Converters

AC/DC Charging Station

Electric Vehicles

Motor controller

High-current battery pack

High-current battery pack

Hybrid electric vehicle

HV Power Distribution Units

PTC & Auxiliary

On-Board Charger (OBC)

Inverters

HV Wire Harness

This is not a list of definitions of applications for this product. It represents some of the more common uses.