- Have any questions?

- +86-13173007052

- sales@cnconnectors.com

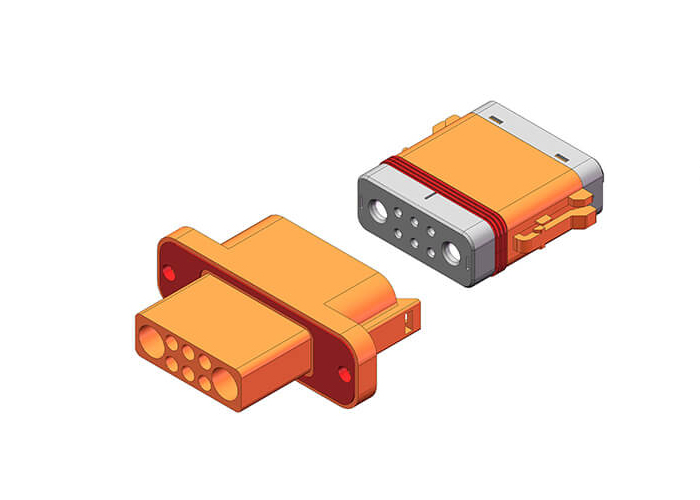

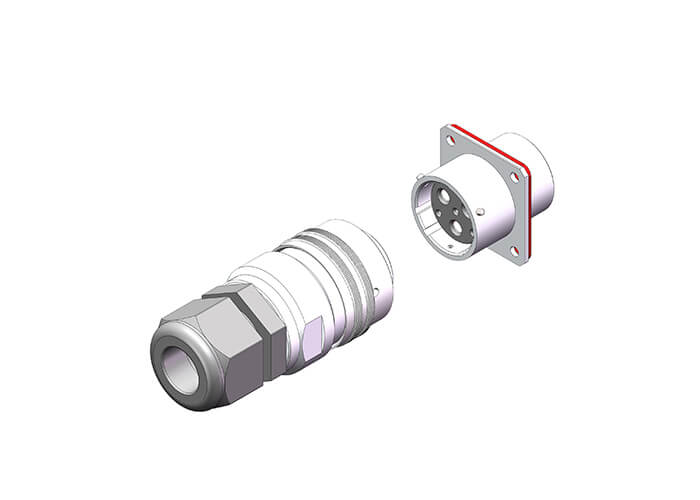

There are two types of automotive connectors

The importance of connector quality safety!

06/05/2021

Application of new energy vehicle connector in automobile

06/16/2021There are two types of automotive connectors

Common automobile connector and new energy automobile connector.

Because new energy vehicles are “green” cars, connectors also require green environmental protection.

In terms of safety, because the connectors of new energy vehicles can withstand up to 250A current and 600V voltage.

The need for a high standard of shock protection is obvious, and at such high power levels, electromagnetic interference is another important issue.

In addition, the operation of plug and unplug can also produce electric arc.

This can cause serious damage to electrical connections and electronic equipment, and may cause combustion in the vehicle, all of which require special connector design and development.

New energy vehicle connectors to meet its high performance requirements mainly rely on strict design specifications.

For example, in the case of exposure to prevent high pressure decomposition of air, this requires the preservation of a certain air gap.

In the case of high voltage and large current, the temperature rise cannot exceed the rated value.

In the selection of shell materials to consider weight, strength and whether easy to process, and at different temperatures.

How to keep the material properties of the lower joint terminal stable, how to ensure the necessary electrical conductivity and so on need to be considered.

In terms of connectivity, the ability to transmit high-speed data is becoming increasingly important as automotive entertainment systems continue to expand,

For example, a camera has been installed in some models’ rearview mirrors to give drivers a wider field of view,

This requires a connector to transmit more data, and sometimes a connector to transmit both GPS and broadcast signals

The connector also needs to be able to withstand high temperatures, because the car’s engine is usually located in the front of the car, and some of the heat gets passed on despite the firewall.

In addition, the “harsh” requirements for new energy vehicle connectors are also reflected in their lives,

Connectors generally have elastic elements that lose their effectiveness after a certain number of plugs.

Therefore, the service life is generally about 3-5 years, while a car can use 10-20 years.

Therefore, the life of the automobile connector must be equal to the life of the automobile, and the requirements for the connector are quite high.